Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Groupes de Produits

Envoyer Une Demande

Type de paiement: L/C,T/T

transport: Ocean,Land,Air,Express

| Material | |

| Types | |

| Contacter Maintenant |

Modèle: ASTM B462 C276/N10276

marque: Groupe Yuhong Chine

Lieu D'origine: Chine

La Norme: Comme moi

Specification: ASTM B462

Material: Hastelloy C-276/ N10276

Size: Depends On Clients' Request

Application: Petrochemical/Chemical/Nuclear Power Plant/Oil And Gas Industry

Face Type: Raised Face

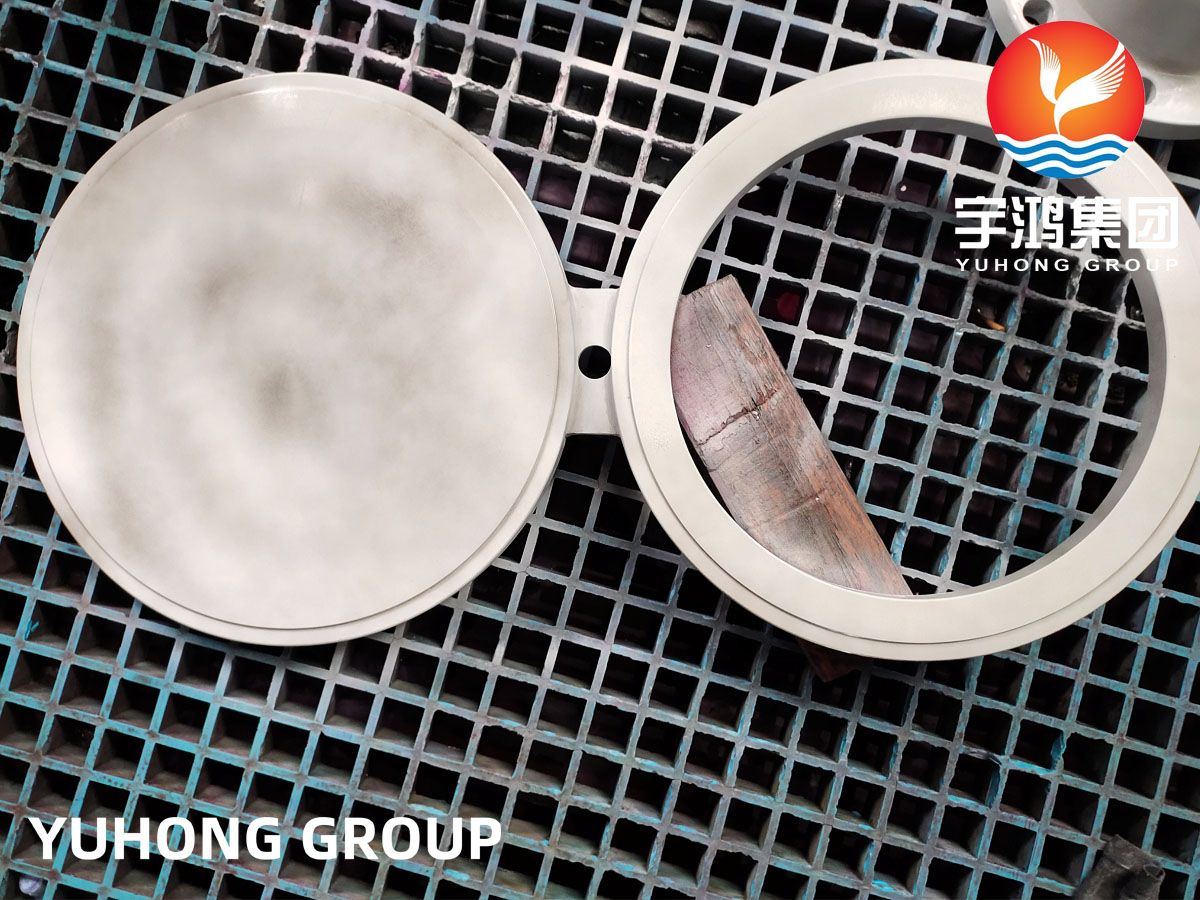

Nom du produit: Hastelloy Spectacle Blind Flange

Le B 564 N10276 Slip on Brid a également la capacité de fonctionner sous une contrainte mécanique élevée en tandem avec des réglages à température élevés. De plus, la bride aveugle ASME SB564 UNS N10276 est utilisée dans les applications qui nécessitent une stabilité de surface élevée.

|

B564 N10276 Flange Size Chart |

1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|

B564 UNS N10276 SORF Flange Standards |

ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

|

B564 gr. N10276 Flange Pressure Rating ANSI |

Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

|

ASTM B564 UNS N10276 Flange Pressure Calculation in DIN |

6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

|

ASTM B564 N10276 Flange JIS |

5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

|

ASTM B564 N10276 Flange UNI |

6Bar 10Bar 16Bar 25Bar 40Bar |

|

SB564 N10276 FlangeEN |

6Bar 10Bar 16Bar 25Bar 40Bar |

|

Coating |

Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

|

Most common types of SB 564 UNS N10276 Flange |

Forged / Threaded / Screwed / Plate |

|

Test Certificates |

EN 10204/3.1B |

|

ASTM B564 UNS N10276 Flange Production technique |

· Forged, Heat treated and machined |

|

B564 UNS N10276 Flange Connect Type/ Flange Face Type |

Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

|

Special design |

As per your drawing

AS, ANSI, BS, DIN and JIS |

|

Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 |

|

|

Nominal Size |

Outside Diameter |

Min. Thickness |

RF Dia. |

No. of Bolt Holes |

Diameter of Holes |

Bolt Circle |

SO Bore ID |

WN Bore ID |

Dia. Hub Base |

Dia. Hub Top |

SO LTH |

WN LTH |

|

1⁄2 |

3.75 |

0.50 |

1.38 |

4 |

0.63 |

2.62 |

0.88 |

0.62 |

1.50 |

0.84 |

0.81 |

2.00 |

|

3⁄4 |

4.62 |

0.56 |

1.69 |

4 |

0.75 |

3.25 |

1.09 |

0.82 |

1.88 |

1.05 |

0.94 |

2.19 |

|

1 |

4.88 |

0.62 |

2.00 |

4 |

0.75 |

3.50 |

1.36 |

1.05 |

2.12 |

1.32 |

1.00 |

2.38 |

|

11⁄4 |

5.25 |

0.69 |

2.50 |

4 |

0.75 |

3.88 |

1.70 |

1.38 |

2.50 |

1.66 |

1.00 |

2.50 |

|

11⁄2 |

6.12 |

0.75 |

2.88 |

4 |

0.88 |

4.50 |

1.95 |

1.61 |

2.75 |

1.90 |

1.13 |

2.63 |

|

2 |

6.50 |

0.81 |

3.62 |

8 |

0.75 |

5.00 |

2.44 |

2.07 |

3.31 |

2.38 |

1.25 |

2.69 |

|

21⁄2 |

7.50 |

0.94 |

4.12 |

8 |

0.88 |

5.88 |

2.94 |

2.47 |

3.94 |

2.88 |

1.44 |

2.94 |

|

3 |

8.25 |

1.06 |

5.00 |

8 |

0.88 |

6.62 |

3.57 |

3.07 |

4.62 |

3.50 |

1.63 |

3.06 |

|

31⁄2 |

9.00 |

1.12 |

5.50 |

8 |

0.88 |

7.25 |

4.07 |

3.55 |

5.25 |

4.00 |

1.69 |

3.13 |

|

4 |

10.00 |

1.19 |

6.19 |

8 |

0.88 |

7.88 |

4.57 |

4.03 |

5.75 |

4.50 |

1.82 |

3.32 |

|

5 |

11.00 |

1.31 |

7.31 |

8 |

0.88 |

9.25 |

5.66 |

5.05 |

7.00 |

5.56 |

1.94 |

3.82 |

|

6 |

12.50 |

1.38 |

8.50 |

12 |

0.88 |

10.62 |

6.72 |

6.07 |

8.12 |

6.63 |

2.00 |

3.82 |

|

8 |

15.00 |

1.56 |

10.62 |

12 |

1.00 |

13.00 |

8.72 |

7.98 |

10.25 |

8.63 |

2.38 |

4.32 |

|

10 |

17.50 |

1.81 |

12.75 |

16 |

1.12 |

15.25 |

10.88 |

10.02 |

12.62 |

10.75 |

2.56 |

4.56 |

|

12 |

20.50 |

1.94 |

15.00 |

16 |

1.25 |

17.75 |

12.88 |

12.00 |

14.75 |

12.75 |

2.82 |

5.06 |

|

14 |

23.00 |

2.06 |

16.25 |

20 |

1.25 |

20.25 |

14.14 |

13.25 |

16.75 |

14.00 |

2.94 |

5.56 |

|

16 |

25.50 |

2.19 |

18.50 |

20 |

1.38 |

22.50 |

16.16 |

15.25 |

19.00 |

16.00 |

3.19 |

5.69 |

|

18 |

28.00 |

2.31 |

21.00 |

24 |

1.38 |

24.75 |

18.18 |

17.25 |

21.00 |

18.00 |

3.44 |

6.19 |

|

20 |

30.50 |

2.44 |

23.12 |

24 |

1.38 |

27.00 |

20.20 |

19.25 |

23.12 |

20.00 |

3.69 |

6.32 |

|

22 |

33.00 |

2.57 |

25.25 |

24 |

1.63 |

29.25 |

22.22 |

21.25 |

25.25 |

22.00 |

3.93 |

6.43 |

|

24 |

36.00 |

2.69 |

27.62 |

24 |

1.63 |

32.00 |

24.25 |

23.25 |

27.62 |

24.00 |

4.13 |

6.56 |

|

B564 N10276 Flange |

ASTM B564 UNS N10276 Blind Flange |

|

B564 UNS N10276 Slip on Flange |

ASTM B564 N10276 Threaded Flange |

|

B564 N10276 Reducing Flange |

ASME SB 564 N10276 Socket Weld Flange |

|

ASTM B564 N10276 Weld Neck Flanges |

ASTM B564 UNS N10276 Lap Joint Flanges |

|

ASTM B564 N10276 Long Weld Neck Flanges |

B564 N10276 Spectacle Blind Flanges |

|

ASTM B564 N10276 Spades & Ring Spacers |

ASME SB 564 N10276 Nipoflange |

|

ASTM B564 UNS N10276 5D Weldoflange |

ASME SB564 N10276 Flange Outlet |

|

B564 N10276 Forged Flanges |

SB564 N10276 Plate Flange |

|

B564 N10276 Ring Type Joint Flanges |

ASME SB 564 N10276 Raised Face Flanges |

|

ASTM B564 UNS N10276 Tongue and Groove Flanges |

SB564 N10276 Male and Female Flange |

|

ASTM B564 N10276 Reducing Flanges |

B564 N10276 ASME B16.5 Flanges |

|

ASME SB564 N10276 Flanges |

B564 UNS N10276 BS 10 Flanges |

|

ASTM B564 UNS N10276 BS 4504 Flanges |

ASME SB 564 N10276 EN 1092-1 Flanges |

|

ASTM B564 N10276 SORF Flange |

B564 N10276 BLRF Flange |

|

ASME SB564 N10276 WNRF Flange |

B564 UNS N10276 RTJ Flange |

|

ASTM B564 UNS N10276 Series a Lap Joint Ring Flange |

ASME SB 564 N10276 Class 300 threaded flange |

|

B564 N10276 PN16 blind flange |

B564 gr. N10276 Forged Socket Weld Pipe Flange |

|

ASTM B564 UNS N10276 Class 300 slip on flange |

ASTM B564 N10276 Slip On Weld Flange |

|

B564 UNS N10276 Forged steel slip on flanges |

B564 UNS N10276 Race face slip on flange |

|

ASME SB564 N10276 SWRF Flange |

B564 gr. N10276 Forged blind flange |

|

ASTM B564 UNS N10276 groove weld neck flange |

ASTM B564 N10276 Socket Weld Hub Flange |

|

ASME SB564 N10276 threaded lap joint flange |

B564 Gr. N10276 Slip On Integral flange |

|

ASTM B564 UNS N10276 Forged integral puddle flange |

B564 UNS N10276 table e long weld neck |

|

B564 N10276 Class 150 LBS Flange |

SB564 N10276 PN10 Forged Flanges |

|

ASTM B564 UNS N10276 RTJ Flanges |

ASTM B564 N10276 PN10 Plate Flanges |

|

B564 N10276 Tongue & Groove Flanges |

ASTM B564 UNS N10276 Reducing Flanges |

|

B564 UNS N10276 Class 150 reducing threaded flange |

B564 UNS N10276 Class 150 Pipe Flange |

|

ASTM B564 N10276 Class 150 Flange |

B564 gr. N10276 Pipe Flanges |

|

B564 N10276 BS 10 Flanges |

SB 564 UNS N10276 Class 150 Tongue & Groove Flanges |

|

B564 UNS N10276 BS 4504 pn16 flange |

B564 N10276 EN 1092-1 flat flange |

|

B564 gr. N10276 Raised Face Flanges |

ASTM B564 N10276 Flat Faced Plate Flanges |

|

ASME SB 564 N10276 Bleed Rings |

B564 N10276 Class 150 Weldoflange |

|

B564 UNS N10276 Class 150 LBS Nipo Flange |

B564 N10276 Long Weld Neck Flanges |

|

ASTM B564 N10276 Lap Joint Pipe Flanges |

ASTM B564 N10276 PN16 Screwed Flanges |

Grades équivalents pour les tubes C276 en alliage Hastelloy:

|

STANDARD |

UNS |

WNR. |

AFNOR |

EN |

JIS |

OR |

GOST |

|

Hastelloy C276 |

N10276 |

2.4819 |

- |

NiMo16Cr15W |

NW 0276 |

ЭП760 |

ХН65МВУ |

Composition chimique

|

Hastelloy C276 |

Ni |

C |

Mo |

Mn |

Si |

Fe |

P |

S |

Co |

Cr |

|

Balance |

0.010 max |

15.00 – 17.00 |

1.00 max |

0.08 max |

4.00 – 7.00 |

0.04 max |

0.03 max |

2.5 max |

14.50 – 16.50 |

Propriétés mécaniques

|

Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

|

8.89 g/cm3 |

1370 °C (2500 °F) |

Psi – 52,000 , MPa – 355 |

Psi – 1,15,000 , MPa – 790 |

40 % |

Applications

1. Contrôle de la pollution Louleurs de pile, conduits, amortisseurs, épurateurs, manufactures à gaz pile, ventilateurs et boîtiers de ventilateurs.

2. Systèmes de désulfuration des gaz de combustion.

3. Composants de traitement chimique comme les échangeurs de chaleur, les récipients de réaction, les évaporateurs et la tuyauterie de transfert.

4. puits de gaz acide.

5. Production de pulpe et papier.

6. Traitement des déchets.

7. Équipement pharmaceutique et de transformation des aliments.

Détails d'emballage: Boîtier de pli-wooden / boîtier en fer / faisceau avec capuchon en plastique

productivité: 50tons Per Month

transport: Ocean,Land,Air,Express

Lieu d'origine: Chine

Soutenir: According to Client's Request

Certificats : ABS, GL, DNV, NK, PED, AD2000, GOST9941-81, CCS, ISO 9001-2008

Code SH: 7507200000

Type de paiement: L/C,T/T

Incoterm: FOB,CIF,EXW,CIP,Express Delivery

Entrer en contact

If you have any questions our products or services,feel free to reach out to us.Provide unique experiences for everyone involved with a brand.we’ve got preferential price and best-quality products for you.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.